Start-up - After Shutdown

Description

Procedures must be provided for the start-up of a process after maintenance or emergency events (Scholtz & Maher, 2014).

Maintenance or emergency events often include shutdown, draining, depressurizing, purging, and isolating to enable the opening of equipment and piping for inspection or repair.

Steps of these procedures are often considerably more detailed than other types of start-up procedures (Scholtz & Maher, 2014).

Unique Considerations (Peres et al., 2016)

- Operators may be unfamiliar with the procedures

- Operators may experience elevated stress due to the uncertainty of these start-up operations

- Process excursions may occur which require the operator to take corrective actions rather than follow the procedure steps

- Possible errors and omissions related to maintenance activities may exist that the operator does not know about

- Pre-start-up activities and reviews that the operator is unfamiliar with for a particular process or piece of equipment may need to occur checklists

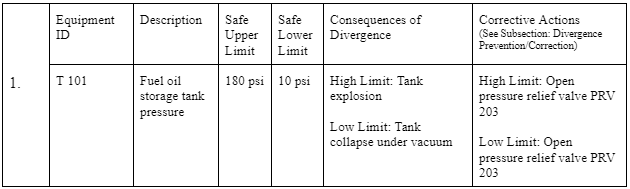

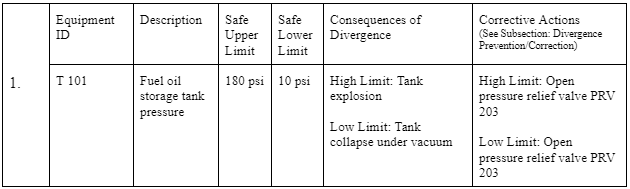

Guideline: Process Excursion Information

Start-up after shutdown procedures should include information about process excursions that may occur as well as the appropriate corrective actions to be taken.

Support

Including information about possible process deviations as well as the appropriate corrective actions prevents the operator from having to rely on judgement or check other reference materials and increases the likelihood of the appropriate corrective actions being taken (Wogalter, 1999).

Example