Operations - Emergency

Description

Procedures must be provided for emergency operations, which are operations that must occur in the event of process upsets or hazards that cannot be addressed with normal or temporary operations procedures (CCPS, 1996)

Abnormal operations requiring action in lieu of or in addition to emergency shutdown should be defined in the procedure (Scholtz & Maher, 2014).

Development of emergency operations procedures in advance prepares operators for emergency circumstances and enables the facility to confirm that appropriate action can be taken (CCPS, 1996)

Unique Considerations (Peres et al., 2016)

- Provisional procedure deviation required as result of dynamically changing situations

- Unfamiliarity of operators with emergency procedures

- Immense time pressure often exists

- Pressure may exist to consider the plant, process, equipment, and product above personal safety

- Possible failure in leadership may occur, resulting in panic and/or indecision

- Communication challenges may result from process excursions or other chaotic conditions

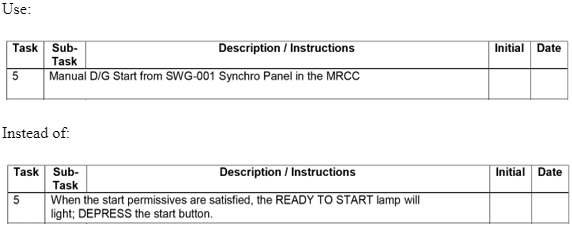

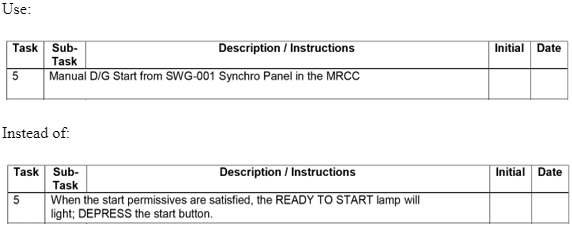

Guideline 1: Emergency Procedure Steps

Write emergency procedures using steps that are as concise as possible.

Support

Workers in emergency situations find complex steps more difficult to execute due to psychological factors which include stress and time pressures (Park, Jung, Kim, Ha, & Shin, 2001).

Example

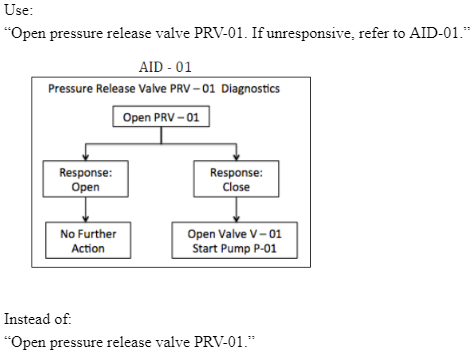

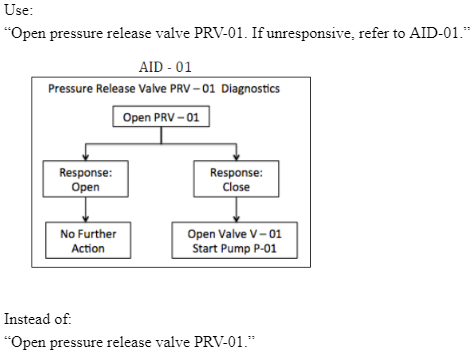

Guideline 2: Emergency Procedure Aids

Emergency procedures should contain information or decision-making aids (e.g., diagnostic flowcharts) for use when unexpected problems occur.

Support

When writing procedures, it is expected that there will be rare or unforeseen situations for which there is not a procedure written. In these situations, workers will experience higher than normal cognitive load and benefit from training and the use of decision aids when responding to emergency situations (Roth, Mumaw, & Lewis, 1994).

Example