Start-up - Initial

Description

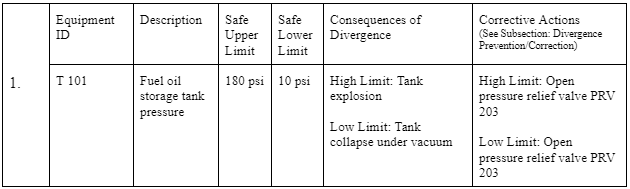

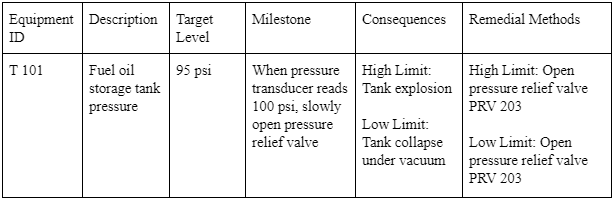

Detailed procedural steps must be provided for initial start-up of processes (Scholtz & Maher, 2014).

- The greatest number of incidents occur during start up (and shut down) procedures, so these procedures must be very clear and accurate (Rowe, 2019).

The initial start-up procedure should be used for training and evaluation under Process Hazard Analysis (PHA) and Management of Change (MOC) processes, as well as for the actual operation itself.

Initial start-up procedures should include target levels, milestones, consequences, and remedial methods (Cruz-Guerra and Cruz-Gomez, 2002). These components should be updated as necessary when management of change processes occur.

Operators are more likely to use procedures for initial start-up than for more frequently performed task procedures, as they have less familiarity with the information (Sasangohar, et al., 2016).

Unique Considerations (Peres et al., 2016)

- Operators may be unfamiliar with the procedures.

- Process excursions can occur which require actions to return the operation to a safe operating window.

- Operators may experience elevated stress due to the uncertainty involved with maiden operations.

- Possible overlooked or unanticipated hazards may exist.

- Initial start-up may be performed by or with other stakeholders as well as the operator.

- Initial start-ups are often conducted at a slower pace with more attention given to individual details than future start-ups.

- Lessons learned during initial startups should be captured and incorporated into future operating procedures.

Guideline 1: Start-Up Procedure Information Inclusion

Support

Example

Guideline 2: Image and Diagram Use

Support

Example