Operating Limits

Procedures within the purview of this writer’s guide that involve outside operational tasks should contain all limits related to the process addressed by the procedure to prevent operators from relying on their memories for the values (Scholtz & Maher, 2014).

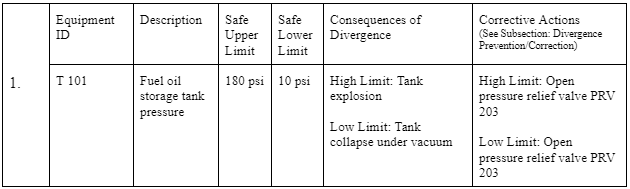

Common practice is for limits to be written in tabular form, with consistent units for each type of dimension.

Limits should contain the following information (Cruz-Guerra & Cruz-Gomez, 2002):

- Equipment identification

- Description of limit

- Numerical value(s) of limit with units

Common practice is for limits that are automated to not be located within the procedure itself, but accessible in such locations as reference manuals.

With these limits included, operators are able to determine (Cruz-Guerra & Cruz-Gomez, 2002):

- Whether a process is in a safe and acceptable state

- If a process-related measurement is approaching divergence from expected/safe levels

- When parameters are outside of limits and corrective actions should be taken

Without these limits included, operators may (Dowell, 2001):

- Attempt to rely on their memory for them, which can lead to incorrect recollection

- Fail to take proper corrective actions

Guideline: Limit Inclusion

Support

Example