Recommended Improvements

In many organizations, equipment and operating conditions are constantly changing (CCPS, 1996).

Once procedures have been written and published, they must be kept up to date.

Procedures must be proactively updated, rather than only after an incident has occurred (API RP, 2004; EPA, 1999; OSHA, 1970).

Procedures must be reviewed annually or more frequently and modified when a change in operating practice, equipment, materials, or other relevant change occurs (API RP, 2004; EPA, 1999; OSHA, 1970).

With this information, workers are:

- Able to complete the procedure correctly, with current information regarding the equipment

- Made aware of changes to the procedure

Without this information, workers are:

- Unable to perform the procedure correctly, and have a higher chance of safety or performance quality issues

- More likely to abandon the use of a procedure because it is insufficient, incorrect, or has incorrect elements (Ockerman, 2007)

Guideline: Updates for Procedure Changes

Procedures must be updated when changes occur to the process that make any steps invalid or unclear.

Support

Workers are more likely to deviate from a written procedure if they perceive the procedure steps to be insufficient or inaccurate (Ockerman, 2007; Bullemer & Hajdukiewicz, 2004).

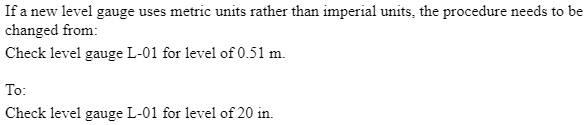

Example

Guideline: Procedure Redlining

Worker response to the redlining of procedures is an indicator of culture within the facility.

Support

Workers are less likely to respond to redlining if it is not done in a timely manner or addressed sufficiently.

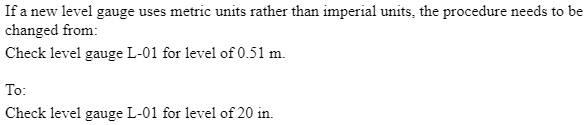

Example

Some company redlining processes take a couple weeks while some take up to six months (Peres, et al. 2020).